◀️ Previous Article | ▶️ Next Article | 📚 The Series Index

Executive Summary

Houston is one of the few places on earth where cheap energy, heavy industry, port logistics, and technical institutions line up strongly enough to make it a genuine “decarbonization lab.” This article turns that thesis into an implementation blueprint built around three tightly coupled systems: Machine-readable Industrial Passports (MIP) as the trust layer, a Manufacturing Value Density Covenant as the coordination layer, and the Houston Industrial Network (HIN) as the data and execution layer.

A three-phase roadmap (2025–2035) defines explicit go/no-go gates: capital deployed, firms enrolled, workers retrained, certified products shipped, and export contracts won. MIP provides product-level forensic traceability for CBAM-exposed exports. The Covenant hard-wires workforce and transition funding through a 1.5% payroll levy and enforceable hiring and automation clauses. HIN uses federated data infrastructure to cut integration time, automate Scope 3 accounting, and coordinate resilience during shocks.

Stress tests—fraud, federal policy reversal, ERCOT failure, and Chinese price undercutting—probe whether the architecture survives real-world failure modes rather than assuming smooth progress. The model concludes that while Houston’s specific advantages are not fully replicable, the pattern is: build trust infrastructure, coordination rules, and workforce systems together, or the flywheel never spins.

Introduction: From Theory to Implementation

Consider a Houston valve manufacturer preparing to bid on a North Sea wind farm contract in late 2025. The buyer—a Danish utility under EU Carbon Border Adjustment Mechanism (CBAM) pressure—requires proof that steel components don't originate from regions using forced labor and that the product's carbon footprint qualifies for green subsidies. Traditional certifications demand stacks of paper documents, 3-6 month third-party audits, and €50,000+ in fees.

But this manufacturer carries a different credential: a Level 3 Machine-readable Industrial Passport (MIP) with blockchain-linked forensic traceability data already verified by Southwest Research Institute. The buyer scans a QR code, verifies the supply chain in minutes, and the manufacturer wins the contract—capturing a green premium. McKinsey's 2024 surveys indicate that 30-40% of steel and aluminum buyers express willingness to pay premiums for low-carbon materials; in constrained markets where supply fails to meet demand, realized premia in the mid-single to low-double digits have been observed. This analysis assumes a 15-20% premium as an upper-bound scenario representing tight market conditions.

This is the trust layer that enables Houston's export strategy. But how do you actually build it?

The previous article in this series established Houston's six-dimensional advantages (energy, robotics, algorithms, maintenance, position, cognition) and diagnosed the three-loop flywheel mechanism that could convert these into sustained competitive dominance. This article provides the operating system: a detailed implementation architecture showing how Machine-readable Industrial Passports (MIP), manufacturing value density covenants, and the Houston Industrial Network (HIN) work in practice.

What distinguishes this from typical policy proposals is the go/no-go gate structure: specific measurable milestones that must be achieved before resources flow to the next phase. The architecture treats decarbonization not as inevitable progress but as an engineering problem requiring stress-testing against real failure modes.

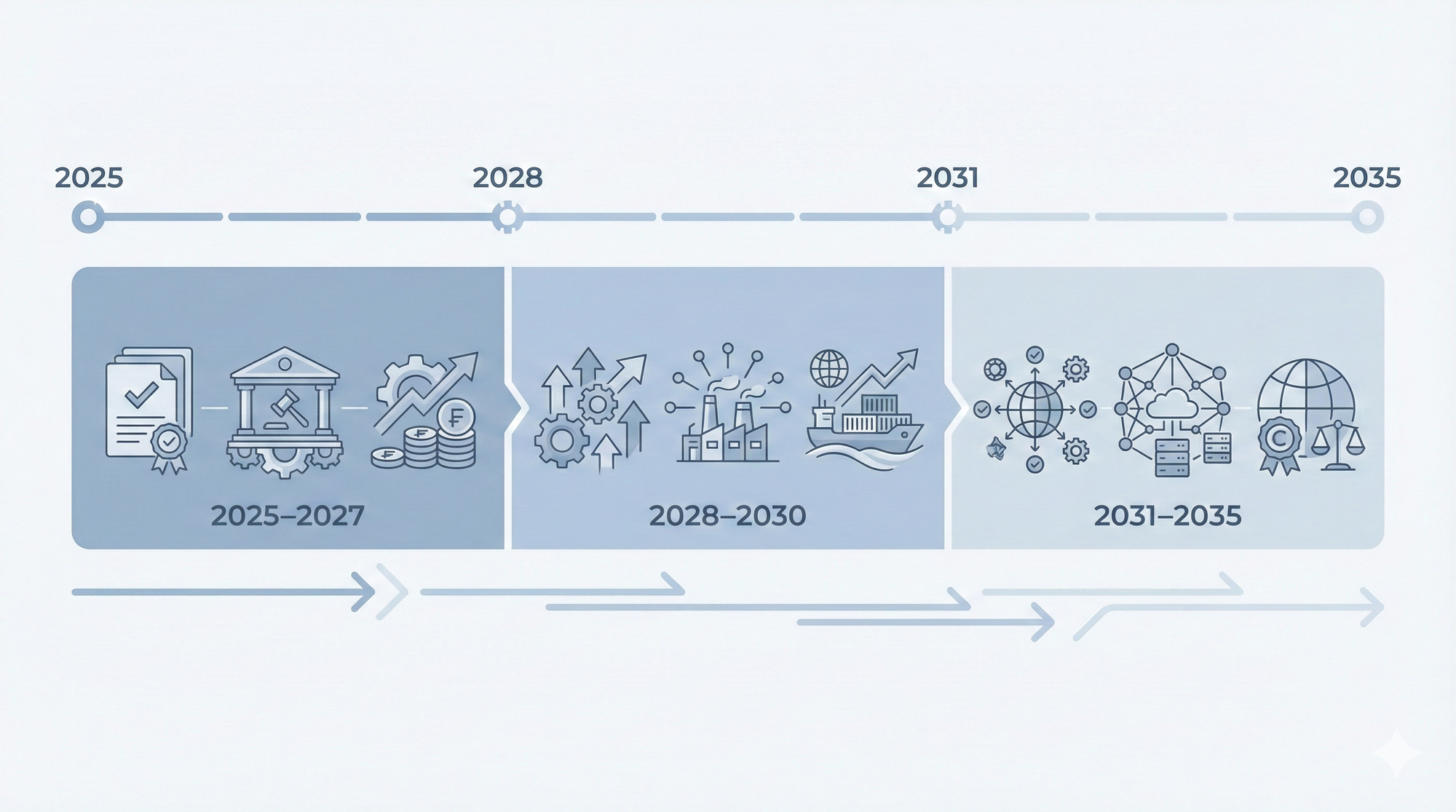

I. Three-Phase Roadmap (2025-2035)

Phase 1: Foundation and Proof of Concept (2025-2027)

Timeline: 27 months (chosen to align with federal funding cycles—long enough to deploy infrastructure, short enough to demonstrate results before 2028 election cycle disruptions)

Primary Objectives:

- Establish governance structures for all three systems

- Deploy Level 1-2 MIP infrastructure with initial certification capacity

- Launch Houston Industrial Training Fund (HITF) with first cohort

- Achieve technical de-risking for Phase 2 expansion

Infrastructure Milestones:

In this proposed framework, Port Houston and U.S. Army Corps of Engineers continue Houston Ship Channel Expansion (Project 11, completion target 2029 per Port Houston timeline). The digital integration layer—automated customs documentation systems, IoT cargo tracking, and MIP-enabled processing—proceeds independently of physical channel expansion, enabling faster deployment. As Port Houston leadership has emphasized in national advisory committee presentations, the port's digitalization initiatives are proceeding in parallel with physical infrastructure expansion, with smart cargo tracking and automated documentation systems being deployed to support future growth capacity.

HyVelocity Gulf Coast Hydrogen Hub continues Phase 1 deployment, representing up to $1.2 billion in federal cost share plus multi-billion private investment according to DOE's 2024 cooperative agreement. As the HyVelocity consortium stated in their DOE award materials, the hub's structure requires "demonstration of commercial viability at each phase before federal funds release for subsequent stages," creating natural alignment with the go/no-go framework proposed here.

Tesla Giga Texas continues expansion. The company plans to invest over $10 billion in the facility over time, with approximately $5-6 billion deployed through 2024 according to local economic development reports. Tier 1 and Tier 2 suppliers invest in co-located facilities: Companies like Futronic are planning combined $28 million investments, including $11 million in real estate and $17 million in manufacturing equipment, to support Tesla's local supply chain deepening.

Governance Establishment:

In this proposed framework, Houston Industrial Network Association forms as 501(c)(6) entity with 17-seat board structure:

- 9 strategic seats: major manufacturers (Tesla, Exxon, Shell, etc.)

- 6 general seats: elected from member base via weighted voting

- 2 community representatives (appointed by Houston Energy Transition Initiative) with binding veto power on HITF fund allocation decisions affecting workforce equity

While community representatives lack votes on technical standards decisions, the veto mechanism ensures labor voice in redistribution policy. This separation recognizes that technical governance requires industry expertise, while equity governance requires community power. The veto applies specifically to HITF spending proposals; a simple majority can propose, but community representatives can block if allocations don't meet workforce development commitments.

The association owns Houston Industrial Training Fund (HITF), capitalized by Manufacturing Value Density Covenant contributions. Initial three-year budget: $80-100M (1.5% of participating firms' manufacturing payroll, estimated $5.5-6.5B aggregate). After 30% allocation to administrative costs, direct support, and reserve requirements, approximately $24.5 million funds immediate worker support in Phase 1, leaving $55-75 million for program expansion, infrastructure grants to community colleges, and emergency reserves.

Financial Commitment Gate (Go/No-Go #1):

Before advancing to Phase 2, Houston Industrial Network must demonstrate:

- Minimum 500 member firms enrolled, representing $50B+ annual revenue

- HITF fund collection $80M+ committed over 36 months

- Community college partnerships signed with San Jacinto College, Lone Star College, Houston Community College (target: establish at least 2 new vocational programs in automation maintenance and industrial robotics technician certifications, drawing on similar program expansion patterns San Jacinto College demonstrated adding 4 new programs between 2018-2023)

- First cohort: 500 workers placed in training programs (500-worker pilot is sized to test administrative capacity—large enough to generate statistically meaningful placement data, small enough to manage intensively)

MIP System Initialization:

In this proposed framework, Southwest Research Institute (SwRI) achieves ISO 17065 accreditation as first Conformity Assessment Body (CAB) for Houston MIP system. Level 1 and Level 2 certifications deploy in pilot mode with 50-100 early adopter firms. SwRI establishes baseline certification protocols and pricing (estimated $10-30K for Level 1, $100-250K for Level 2, based on comparable third-party industrial certification fee structures), with costs potentially subsidized through HITF for qualifying small manufacturers.

The proposed architecture provides for MIP Cost-Sharing Program: HITF allocates $5-10 million annually for small supplier subsidies. Firms with fewer than 200 employees and less than $50 million revenue qualify for 50% reimbursement of Level 2-3 certification costs, capped at $125,000 per firm. This addresses the capital barrier that would otherwise exclude smaller manufacturers from premium export markets, enabling them to absorb net costs of $50-125K over a 2-3 year amortization period while accessing higher-margin contracts.

Covenant Pilot Deployment:

First wave: 15-20 anchor manufacturers sign Manufacturing Value Density Covenant. Enforcement mechanisms activate but with 12-month grace period for compliance ramp-up. Estimated aggregate contribution in Year 1: $25-30M based on pilot group's combined manufacturing workforce.

Phase 2: Scale and Market Validation (2028-2030)

Market Penetration Gate (Go/No-Go #2):

Phase 2 activation requires demonstrated market traction:

- MIP uptake: 200+ Houston manufacturers hold Level 1-2 certification

- Market validation: At least 10 EU/Asia buyers explicitly require or prefer MIP in RFPs

- Export revenue: Member firms collectively demonstrate $500M+ in MIP-enabled export contracts

- Training outcomes: First cohort 75%+ placement rate in manufacturing roles at $50K+ annual wage

MIP System Expansion:

In this proposed framework, Houston accredits second and third CABs: Intertek Houston, TÜV SÜD America. Competition among three CABs drives pricing efficiency and service quality. Level 3 certification (forensic supply chain verification, real-time carbon accounting) becomes available.

Economic model of Level 3 MIP value proposition (illustrative scenario based on observed green materials market dynamics):

A mid-size specialty steel processor exports 10,000 kg/month of certified green steel products. Assuming a 15-20% premium in tight markets where green supply constraints drive premium pricing:

Base revenue: 10,000 kg × $10/kg = $100,000/month

With 15-20% premium: $15,000-20,000 additional monthly revenue

Level 3 MIP certification investment: $100-250K (cost breakdown: forensic supply chain audits $200-800, labor compliance verification $150-400, third-party CAB fees $100-300, ongoing monitoring systems $50-500/year)

Payback period: approximately 5-13 months if full premium captured. This scenario assumes sustained market demand for certified green products and effective marketing of MIP credentials to buyers. For firms with less than $50M revenue qualifying for HITF subsidies, net investment drops to $50-125K, reducing payback to 2.5-6.5 months.

This supply chain transparency dimension has been a persistent challenge for many exporters seeking to enter premium EU and US markets under enhanced regulatory scrutiny. MIP's structured verification pathway provides documentary evidence that traditional exporters struggle to assemble credibly.

HIN Technical Deployment:

Houston Industrial Network Operating Company (HIN OpCo) spins off as independent technical operator. Revenue structure: $10K one-time Eclipse Dataspace Connector (EDC) setup fee (generating $5M from 500 initial members) plus $5K annual connector licensing (generating $2.5M recurring revenue), supporting 15-20 FTE technical team.

Federated data architecture deploys based on Eclipse Dataspace Components and International Data Spaces (IDS) protocols developed by Fraunhofer IAIS. Early IDS-style implementations in German automotive supply chains have reported substantial reductions in bespoke integration effort compared to traditional Electronic Data Interchange (EDI) systems. Observed reductions in one-off data mapping work range from 50-80% in pilot deployments, representing a plausible upper-bound scenario for what federated architecture could achieve at scale rather than guaranteed average performance. These estimates, drawn from European automotive clusters rather than Houston-specific implementations, provide directional guidance on potential efficiency gains.

Key technical capabilities:

- Supplier onboarding: Target timeline 2-4 weeks (compared to typical 4-6-month EDI onboarding cycles observed in traditional supply chain integration)

- Data sovereignty: Each firm controls access policies via local EDC instance

- Interoperability: REST APIs enable integration with SAP, Oracle, custom MES systems

- MIP integration: Automated verification pulls from SwRI/Intertek/TÜV databases

Covenant Enforcement Ramp-Up:

Membership expands to 50-75 signatory firms. Covenant administrator (Houston Industrial Network Association, supported by 3-5 FTE compliance team) begins active enforcement of all five clauses. First dispute resolution cases processed through three-tier system.

Phase 3: Global Replication and System Maturity (2031-2035)

System Maturity Gate (Go/No-Go #3):

Transition to Phase 3 requires proof of self-sustaining ecosystem:

- Financial sustainability: HIN OpCo achieves operational break-even on membership fees

- International recognition: MIP credentials accepted by buyers/regulators in 10+ countries

- Deep supply chain integration: 60% of Houston manufacturing base participates in at least one system

- Workforce evidence: HITF demonstrates 70%+ long-term placement rate (5-year tracking)

Global Service Layer:

In this proposed architecture, HIN OpCo spins off subsidiary: HIN Global Services, offering MIP certification consulting and HIN connector deployment to other regions. Revenue model: setup fees + licensing + training services. Target markets: Appalachian hydrogen economy (West Virginia, Ohio, Pennsylvania), Permian Basin industrial clusters, international partners in Middle East (UAE, Saudi Arabia), Southeast Asia (Vietnam, Indonesia).

The model assumes SwRI establishes "MIP Academy"—training program to certify international CABs in MIP protocols. Goal: 10-15 accredited CABs globally by 2035, creating network effects where MIP becomes de facto standard for industrial carbon accounting. This replication model is similar to how ISO 17065 accreditation spread internationally, but accelerated through digital verification infrastructure.

Workforce Replication:

Other regions adapt HITF model. In the proposed framework, federal DOE or DOL provides $500M "Industrial Transition Fund" matching grants to regional coalitions replicating Houston model. This would represent roughly 10-15% of typical federal workforce development spending in manufacturing sectors, reallocated toward "place-based, sector-specific" models vs. diffuse national programs.

II. Machine-Readable Industrial Passport: Technical Architecture

Returning to the three-system model outlined above, the Machine-readable Industrial Passport serves as the trust foundation. Unlike traditional certifications that function as static documents, MIP operates as a living data structure that evolves with the product.

Three-Level Security Architecture

Level 1: Basic Carbon Accounting

- Verification standard: ISO 14064-1 (greenhouse gas accounting)

- Data requirements: Facility-level Scope 1+2 emissions, annual verification cycle

- Certification cost: $10-30K annually (based on comparable facility-level GHG verification fee structures)

- Market access: Qualifies for CBAM reporting in EU, satisfies basic ESG disclosure requirements

- Typical users: Mid-size manufacturers with single-facility operations, firms in early stages of decarbonization planning

Level 2: Supply Chain Traceability

- Verification standard: ISO 14067 (product carbon footprint) + OECD Due Diligence Guidance

- Data requirements: Tier 1 supplier emissions data, material origin documentation, quarterly verification cycle

- Certification cost: $50-150K initial, $25-75K annual renewal

- Market access: EU Green Claims Directive compliance, U.S. DOE Hydrogen Hubs supplier eligibility, investment-grade ESG reporting

- Typical users: Tier 1 automotive/aerospace suppliers, specialty chemical manufacturers, firms bidding on large infrastructure projects with strict sustainability requirements

Level 3: Forensic Supply Chain + Real-Time Carbon Accounting

- Verification standard: Full Scope 3 accounting per GHG Protocol + forensic labor compliance audits

- Data requirements: Tier 2-3 supplier data, blockchain-anchored batch traceability, continuous monitoring via IoT sensors

- Certification cost: $100-250K initial (forensic supply chain audits $200-800, labor compliance verification $150-400, third-party CAB fees $100-300), $50-100K annual renewal (ongoing monitoring systems $50-500/year)

- Market access: Premium green product markets, sovereign wealth fund investment eligibility, U.S. Defense Department "trusted supplier" status

- Typical users: Export-focused manufacturers targeting EU premium markets, firms seeking to differentiate in highly competitive bids, suppliers to major OEMs with strict sustainability mandates

Information Architecture

MIP data structure follows W3C Verifiable Credentials standard:

Manufacturing Integrity Credential

📦 Product Info

- Product ID: HOU-MFG-2025-847392

- Issuer: Southwest Research Institute CAB-001

- Issued: 2025-03-15

- Expires: 2026-03-15

- Credential Type: MIP_Level_3

🌍 Carbon Intensity

| Scope 1 | 0.42 tCO₂e/unit |

| Scope 2 | 0.18 tCO₂e/unit |

| Scope 3 Tier 1 | 1.25 tCO₂e/unit |

| Scope 3 Tier 2 | 0.67 tCO₂e/unit |

| Total | 2.52 tCO₂e/unit |

Verified by ISO 14067:2018 on 2025-03-01

🔒 Supply Chain Integrity

- Tier 1 Suppliers: verified

- Tier 2 Materials: steel (verified), aluminum (verified)

- Labor Compliance: OECD-DD compliant

- Conflict Minerals: SEC Rule 13p-1 compliant

🛡️ Trust Anchors

- Blockchain Anchor: ipfs://Qm...

- Digital Signature: CAB_RSA_4096

Integration with Houston Industrial Network

MIP credentials stored in HIN's federated data layer, enabling:

- Automated customs processing: In this proposed framework, U.S. Customs and Border Protection pilots "green lane" for MIP Level 2+ cargo, targeting processing times measured in hours rather than the multi-day cycles that can occur during peak congestion periods. Recent carrier operational data shows Houston import container dwell times around 3.5-4.0 days, with port stakeholders targeting a return to the historical 3-3.5 day range through Saturday gate expansions and improved empty container management.

- Supply chain visibility: OEMs query HIN to verify their Tier 2-3 suppliers' MIP status without direct data access

- Carbon accounting automation: Manufacturers' ERP systems pull supplier carbon data from HIN APIs, eliminating manual Scope 3 calculation

III. Manufacturing Value Density Covenant: Legal and Enforcement Structure

Why five clauses instead of a simpler two or three? Early stakeholder consultations in comparable industrial coordination efforts revealed that partial commitments fail: firms that fund training without hiring obligations simply poach each other's graduates; firms that hire locally without transition support trigger labor shortages during automation. The Covenant's five interlocking clauses address this by ensuring no firm can free-ride on others' investments while avoiding its own obligations.

Five Core Commitments

Clause 1: Capital Investment Density

Signatories commit to minimum $150K capital investment per manufacturing job (measured as 3-year rolling average to smooth cyclical variations). This threshold separates genuine manufacturing value creation from labor arbitrage operations. Rationale for $150K threshold: balances meaningful equipment investment (modern CNC machines, robotics cells, clean energy systems) with accessibility for mid-size manufacturers; comparable to German Mittelstand investment patterns.

Formula:

$$

\text{MVD} = \frac{\text{Total Manufacturing CapEx over 36 months}}{\text{Average Manufacturing Headcount over 36 months}}

$$

$$

\text{MVD}_{\text{minimum}} = 150{,}000

$$

Verification: Annual certification through independent audit (Big 4 firms or equivalent), submitted to Covenant Administrator. Non-compliance triggers $500K penalty per violation year, escalating to expulsion after two consecutive years below threshold.

Clause 2: Training Fund Contribution

1.5% of manufacturing payroll contributed to Houston Industrial Training Fund (HITF). Contribution calculated monthly, paid quarterly. Why 1.5%? This rate is chosen to balance viability—1% proves insufficient for meaningful scale, while 2%+ triggers business opposition based on comparable European apprenticeship levy experiences. The rate approximates Germany's vocational training contributions while remaining below the threshold that historically generates employer coalition resistance.

For firms with $100M manufacturing payroll: $1.5M annual contribution. Funds allocated:

- 40%: Direct training program costs (equipment, instructors, facilities)

- 30%: Income support for workers in transition (approximately two-thirds of gross wages, comparable to Germany's Kurzarbeit short-time work allowance of 60-67% wage replacement)

- 20%: Administrative and placement services

- 10%: Emergency reserve for economic shocks

Clause 3: Local Hiring Preference

Approximately two-thirds of new manufacturing hires from Houston metro region (65% threshold chosen to balance local priority with operational flexibility—70%+ risks talent shortages in specialized roles, 60% insufficient to demonstrate meaningful commitment). "Houston metro" defined as 13-county region to prevent artificial boundary manipulation.

Exception clause: Out-of-region hiring permitted for roles requiring specialized skills not available locally (e.g., advanced robotics programming, hydrogen systems engineering), provided firm demonstrates good-faith local recruitment effort (minimum 90-day search period, minimum 3 qualified local candidate interviews).

Verification: Quarterly reporting to Covenant Administrator with hire location data. Firms consistently below 60% face mandatory remediation plans; persistent non-compliance triggers graduated fines ($50K first violation, $150K second violation, expulsion consideration third violation).

Clause 4: Automation Transition Support

When automation displaces workers (defined as: job elimination directly caused by capital equipment installation reducing labor requirements), firms must either:

- Option A: Offer affected workers retraining + placement assistance + income support during transition (roughly 70% wage support for up to 12 months, modeled on Germany's Kurzarbeit program)

- Option B: Pay severance of 1.5x standard package + additional $10K/worker contribution to HITF retraining pool

Why these options? Option A encourages retention and retraining (preferred outcome), but Option B provides flexibility for firms facing severe cost constraints or workers preferring immediate transition. The 1.5x severance multiplier + $10K contribution ensures firms face real cost for choosing displacement over retention, aligning private incentives with social outcomes.

Economic Policy Institute's 2024 analysis of the Gulf Coast Hydrogen Hub workforce transition noted that "without proactive transition support mechanisms, the shift from fossil to clean energy jobs risks creating a two-tier workforce," highlighting the need for binding commitments rather than voluntary programs. This clause directly addresses that risk through enforceable financial penalties for displacement without support.

Clause 5: Carbon Intensity Improvement

Annual 3% reduction in Scope 1+2 carbon intensity (tCO2e per unit of output), measured against 2025 baseline. Three-year rolling average to account for production mix changes. Rationale for 3% annual target: sufficient to drive meaningful technology adoption (payback period 5-8 years typical for industrial efficiency investments) while remaining achievable through continuous improvement vs. requiring disruptive facility overhauls.

Firms that miss target: Required to purchase carbon offsets for gap (priced at higher-of: $80/tCO2 or prevailing EU ETS price + 20% premium). Persistent misses (3+ years) trigger review of continued Covenant eligibility. This pricing mechanism ensures carbon reduction remains economically rational vs. offset purchasing.

Enforcement Architecture

Three-tier dispute resolution:

Tier 1 - Informal Resolution (Target: 60-90 days) Covenant Compliance Officer (full-time position within HIN Association) mediates between complainant and alleged violator. Historical experience in comparable commercial arbitration contexts suggests that substantial majority of disputes (80-90% based on American Arbitration Association commercial dispute settlement patterns) can be resolved at this stage through facilitated negotiation.

Tier 2 - Formal Arbitration (Target: 120-180 days) Three-arbitrator panel: one selected by each party, third selected jointly (or by HIN Board if parties cannot agree). Arbitration follows AAA Commercial Arbitration Rules. Decision binding, enforceable through Texas state courts.

Tier 3 - Expulsion Review (Rare) HIN Board (requiring 2/3 supermajority) can revoke Covenant signatory status for:

- Persistent non-compliance across multiple clauses

- Fraud in reporting or verification

- Actions materially undermining Covenant's public legitimacy

Expelled firms lose access to HIN data platform, MIP fast-track processing, and collective bargaining power in infrastructure projects. More critically, expulsion creates reputational risk: in proposed framework, major OEMs (Tesla, Boeing, etc.) include Covenant membership as preferred supplier criterion.

Why This Doesn't Violate Antitrust Law

The Covenant occupies the legal grey zone of "ancillary restraints"—agreements that technically restrict competition but serve a legitimate collaborative purpose. Legal analysis based on precedent:

Supporting precedent:

- Broadcast Music, Inc. v. Columbia Broadcasting System (1979): Supreme Court upheld music licensing collective where coordination was reasonably necessary for industry function

- Topco Associates (1972): Though ultimately struck down, established framework for analyzing when coordination serves pro-competitive purposes

Key defensive arguments:

- Non-price coordination: Covenant doesn't fix product prices, wage rates, or customer allocation—traditional per se violations

- Legitimate purpose: Workforce development and supply chain transparency are recognized public goods with positive externalities

- Voluntary participation: Firms can opt out; no market foreclosure for non-participants

- Pro-competitive effects: Enhanced supply chain trust reduces transaction costs, improves market information flow

Residual risk assessment: The risk of FTC review is material given the Covenant's market coordination elements, though full litigation appears less likely than negotiated settlement based on precedents in ancillary restraints cases. Firms should engage antitrust counsel during implementation to ensure ongoing compliance with evolving enforcement priorities.

IV. Houston Industrial Network: Data Architecture and Services

The Fraunhofer Institute's International Data Spaces architecture, upon which HIN is modeled, was explicitly designed to enable what the institute describes as "data sovereignty by design"—where participants retain full control over who accesses their data, under what conditions, and for how long, without requiring centralized data custody.

Federated Data Model (Non-Custodial)

Unlike traditional supply chain platforms (Elemica, e2open, etc.) that aggregate data in central repositories, HIN operates as a federation protocol:

- Data stays local: Each firm operates its own Eclipse Dataspace Connector (EDC), maintaining data within firm's firewall

- Policy-driven access: Firms define granular access rules ("Supplier X can query my production schedules for Part Y, but only 6 weeks in advance, and cannot download raw data")

- Blockchain audit trail: All data access requests logged to immutable ledger, enabling compliance verification without exposing underlying data

- Semantic interoperability: IDS Information Model provides shared vocabulary so different firms' systems can understand each other's data structures

Technical analogy: Email vs. Facebook. Email is federated (you control your own server, set your own rules), Facebook is centralized (they custody your data). HIN is email-style for industrial data.

Core Services

Service 1: Supplier Discovery and Verification

Manufacturer posts requirement: "Need Tier 2 supplier for 10,000 kg/month stainless steel, Level 2 MIP certified, delivery radius <500 miles."

HIN searches federated connectors, returns matches with verified credentials (MIP status, capacity, lead times). Matching algorithm uses semantic reasoning to handle variations ("stainless steel grade 304" vs. "18-8 austenitic steel").

Revenue model: $500 per successful connection facilitation.

Service 2: Automated Scope 3 Carbon Accounting

Manufacturer's ERP pulls carbon intensity data from Tier 1-2 suppliers via HIN APIs. System automatically aggregates into Scope 3 Category 1 (Purchased Goods) calculation per GHG Protocol standards.

Value proposition: Reduces Scope 3 reporting from 200+ hours of manual data collection per year to <20 hours of validation work. For a firm with 200 suppliers, this represents $15-20K annual labor cost savings at typical analyst/engineer rates.

Revenue model: $10K setup + $2K/year per reporting entity.

Service 3: Resilience Monitoring

HIN aggregates anonymized capacity data across members, providing early warning signals:

- "3 of your Tier 2 suppliers are at >90% capacity utilization—consider dual-sourcing"

- "Hurricane forecast suggests 60% probability of Port Houston disruption September 15-20—consider accelerating inbound shipments"

- "ERCOT grid reliability forecast indicates elevated risk week of August 10—consider production schedule adjustments"

This intelligence layer provides asymmetric advantage: HIN members see risks non-members don't. Revenue model: included in base membership, creates strong network effects (value increases with membership density).

Service 4: Training-to-Hiring Pipeline

Integration between HITF training programs and member companies' applicant tracking systems. When worker completes certification (e.g., "Industrial Robotics Technician Level 2"), profile automatically shared with member firms seeking those skills.

Value proposition: Reduces hiring friction, improves placement rates, closes loop between workforce development funding and business hiring needs.

V. Stress Testing the Architecture: Four Risk Scenarios

To test whether the three-system architecture can withstand real-world shocks, consider four scenarios that probe different vulnerability points:

Scenario 1: Major MIP Forgery Scandal (2028)

Triggering event: Investigative journalists discover that a rogue Tier 2 supplier fabricated Level 2 MIP credentials for $50M worth of steel components, bypassing SwRI verification. Components were incorporated into offshore wind projects and hydrogen infrastructure.

System response:

- Immediate: SwRI revokes certificates, HIN platform flags affected batch IDs, downstream buyers receive automated alerts

- Liability: Covenant enforcement mechanism activates—fraudulent supplier expelled, upstream firms that failed due diligence face fines

- Forensic: Blockchain audit trail identifies exact scope of fraud (which buyers received tainted components, when)

- Remediation: SwRI implements enhanced verification (adding material spectroscopy sampling to document audits), increases audit frequency for high-risk suppliers

Outcome: Incident actually strengthens MIP trust because system demonstrated:

- Detectability: Fraud was uncovered (not hidden indefinitely)

- Traceability: Impact scope rapidly determined through HIN data layer

- Accountability: Clear enforcement with financial consequences

- Correction: System adapted protocols to prevent recurrence

However, this optimistic recovery scenario assumes rapid detection and transparent response. If forgery remained undetected for 12-18 months, eroding buyer trust gradually, the damage could be irreparable. MIP's value proposition—trust at scale—makes it vulnerable to trust collapse if verification systems prove penetrable.

Long-term impact: MIP becomes more trusted than paper-based certifications precisely because it has demonstrated and adapted to failure, similar to how aviation safety improves through post-incident analysis.

Scenario 2: Federal Policy Reversal (2029)

Triggering event: New U.S. administration implements 25% tariff on all imported components, eliminates IRA production tax credits, and rolls back CBAM-equivalent border carbon adjustments. DOE freezes remaining HyVelocity funding.

System response:

- MIP value shift: EU/Asian export markets remain, but U.S. domestic premium disappears. MIP becomes primarily export-focused credential.

- HyVelocity adaptation: Private consortium absorbs Phase 2 deployment without federal matching. Scale down from $1.2B to $400-500M program, focus on commercially viable applications (ammonia export, petrochemical decarbonization) rather than aspirational uses.

- Covenant resilience: Workforce development funding continues because signatories derive value from reduced turnover and increased productivity, independent of federal policy.

- HIN strengthening: Actually accelerates adoption because tariffs increase premium on supply chain transparency—firms need to prove "U.S. content" for various trade compliance rules

Outcome: The three-pillar design prevents single point of failure. One pillar (federal green incentives) collapses, but other two (supply chain trust, workforce coordination) continue delivering value. Houston's competitive position narrows from "global decarbonization hub" to "premium manufacturing cluster with unusually transparent and skilled supply chains"—still valuable, just less transformative.

Critical vulnerability identified: If policy reversal is severe enough to make green investments economically irrational (not just subsidy-dependent, but actively value-destroying), the entire model requires recalibration. A federal mandate prohibiting carbon accounting or penalizing green production would create existential crisis.

Scenario 3: Winter Storm Uri 2.0 (2031)

Triggering event: Repeat of February 2021 grid failure, but during peak summer cooling demand. ERCOT blackouts last 5-7 days (vs. 2021's 2-4 days). Tesla Gigafactory, major petrochemical plants offline.

System response:

- Immediate mitigation: HIN's resilience monitoring system provided 72-hour advance warning, allowing firms to pre-stage backup power, accelerate critical production runs, secure generator fuel

- Mutual aid: Covenant signatories with on-site generation (Tesla's 100MW solar + battery, Shell's combined heat and power) provide emergency power-sharing to smaller members, enabled by HIN's real-time capacity tracking

- Supply chain rerouting: HIN platform rapidly identifies alternative Tier 2 suppliers outside affected region, minimizes cascade failures

- Insurance claims acceleration: Because HIN provides auditable production logs, claims processing reduced from 90-120 days to 30-45 days

Quantified impact reduction:

- Production loss: 35-40% vs. baseline prediction of 60-70% without coordination

- Supply chain recovery time: 3-4 weeks vs. 12-16 weeks without HIN-enabled rerouting

- Insurance payout time: 30-45 days vs. 90-120 days traditional process

- Total economic impact: $1.2-1.5B vs. $4-5B uncoordinated scenario (Houston-area manufacturing only, not including residential or other sectors)

However, if ERCOT grid failures become chronic rather than episodic—occurring multiple times per year—no amount of backup power or insurance can sustain investor confidence. At some threshold of infrastructure unreliability, the Houston model becomes unviable regardless of other advantages. The architecture assumes Texas addresses grid reliability as part of parallel infrastructure investment strategy.

Scenario 4: Competitive Arbitrage (Shanghai 2033)

Triggering event: China announces "Shanghai Green Manufacturing Initiative"—$50B state investment in carbon-negative steel and aluminum production. Chinese manufacturers offer certified green products at 15-20% discount to Houston's premium pricing, leveraging state subsidies and captive domestic demand.

System response options:

Option A - Price Competition (Losing Strategy): Houston firms cut prices to match Chinese offers, eliminating MIP premium. HITF funding collapses, Covenant signatories defect, system spirals.

Option B - Value Differentiation (Viable Strategy):

- Trust premium: MIP emphasizes credibility gap: EU/U.S. buyers pay 5-10% premium for independently verified (not state-certified) carbon accounting + labor compliance audits

- Speed premium: HIN's integrated logistics and customs fast-track provide 2-4 week delivery advantage over trans-Pacific shipping

- Resilience premium: Recent supply chain shocks have taught buyers to value geographic diversification; Houston offers "China+1" production redundancy

- Technical services: Houston pivots toward high-complexity, low-volume production where Chinese scale advantages matter less (specialty alloys, rapid prototyping, co-development contracts)

Outcome: Houston doesn't win commodity competition, but sustains premium position in trust-sensitive, time-sensitive, and complexity-intensive applications. Think Switzerland in pharmaceuticals or Germany in machine tools—not the cheapest, but defensibly "worth it" for specific applications.

Critical assumption exposed: This defensive strategy works only if Western buyers continue prioritizing supply chain transparency and labor standards over pure cost. If CBAM enforcement proves weak or political winds shift toward accepting Chinese green certifications at face value, Houston's trust premium evaporates.

VI. Why This Architecture Won't Replicate Everywhere

Houston's specific conditions enable this three-system model. Understanding what can't be replicated clarifies the genuine competitive moat.

Six Necessary Conditions

1. Incumbent Energy Infrastructure Houston's dozens of refineries, hundreds of chemical plants, and extensive pipeline networks provide thermal integration opportunities (waste heat recovery, byproduct utilization) that greenfield sites lack. A new manufacturing cluster built in, say, rural Wyoming would face $500M-1B additional infrastructure costs for equivalent energy density.

2. Deep-Water Port with Direct Gulf Access Houston Ship Channel handles over 300 million tons annually per U.S. Army Corps of Engineers data, ranking as one of the nation's busiest waterways. Port infrastructure provides structural advantages including direct Gulf access and inland connectivity, though recent volume growth has created operational challenges that the industry is actively addressing through capacity expansion and digital integration initiatives. Houston's relatively balanced import-export flows reduce empty container repositioning costs compared to many coastal competitors.

Compare Rotterdam: Superior physical infrastructure but industrial and commercial electricity rates typically 20+¢/kWh all-in for non-household users (2023-2024 data showing ranges of 22-33¢/kWh depending on consumption tier and contract structure per Trading Economics data), versus Houston's 8-9¢/kWh range for industrial and commercial users based on EIA 2024 Texas data. This 2.5-3x energy cost differential makes Houston's energy-intensive manufacturing fundamentally more competitive for carbon-intensive processes like electrolysis, even after accounting for EU carbon border adjustments.

3. Technical Research Infrastructure Southwest Research Institute, University of Houston Energy Research Park, Texas A&M Engineering Extension Service provide certification, testing, and workforce development capabilities typically unavailable in smaller metros. SwRI alone has 2,700+ employees and $700M annual R&D budget—this institutional depth can't be quickly assembled.

4. Scale Economy (Manufacturing Base) Houston metro: approximately 270,000 manufacturing jobs, $50B+ annual output (based on Greater Houston Partnership industrial sector data). This density enables HITF economies of scale (spreading fixed costs across large contributor base) and HIN network effects (value increases exponentially with connected participants). A region with <50,000 manufacturing jobs would struggle to achieve minimum viable scale.

5. Political Economy Tolerance Texas's business culture tolerates public-private coordination structures more than regions with stronger anti-corporatism or stronger unions demanding formal labor representation. The Covenant's industry-led governance with community veto rights (rather than co-equal labor-management boards common in European models) reflects this specific political economy.

6. Crisis-Driven Coordination Imperative Winter Storm Uri and Hurricane Harvey created shared trauma that lowered barriers to coordination. This "burning platform" psychology is hard to manufacture absent actual crisis—and by then, it may be too late to build trust relationships.

What Can Replicate

Despite these Houston-specific advantages, the architectural principles have transferable value:

- Federated data models (HIN-style) suit any industry with fragmented supply chains and proprietary data concerns: aerospace, defense, life sciences, advanced materials

- Triple-validation certification (MIP-style) addresses trust gaps in any trade relationship with high information asymmetry: conflict minerals, labor standards, food safety, pharmaceutical supply chains

- Workforce development funded by sector-specific levies (HITF-style) is proven in European contexts, adaptable to other U.S. manufacturing clusters

The three-system interaction—where trust infrastructure enables higher coordination, which funds workforce development, which attracts investment, which generates tax revenue for more infrastructure—is the transferable insight. The specific implementations must adapt to local conditions.

VII. What Could Derail This Model

Three fundamental assumptions underpin this architecture. If any proves wrong, the model requires major redesign rather than incremental adjustment:

Assumption 1: CBAM Enforcement Will Be Stringent

The economic case for MIP rests on EU buyers paying 10-15% premiums for certified green products. CBAM's transitional phase (October 2023 through December 2025) already requires quarterly emissions reporting with no financial obligations. The definitive regime begins in 2026, requiring importers to purchase CBAM certificates linked to their products' embedded emissions, with first surrender obligations in early 2027. If EU regulators grant broad exemptions or repeatedly delay enforcement, MIP's value proposition weakens substantially.

Monitoring indicator: Track percentage of EU CBAM-covered imports actually paying border adjustments vs. receiving exemptions/delays. If exemption rate exceeds 40%, the premium market may not materialize as projected.

Assumption 2: Texas Political Economy Remains Coordination-Friendly

A shift toward populist hostility to large corporations or federal environmental mandates could fracture the Covenant coalition. If state-level policy actively penalizes carbon accounting or workforce development spending, signatories would face conflicting pressures.

Monitoring indicator: Watch for state legislation restricting ESG considerations in business decisions or prohibiting participation in "climate action" initiatives. Emergence of such bills, even if not passed, signals political wind shifts that could undermine voluntary coordination.

Assumption 3: China Won't Rapidly Close the Trust Gap

Houston's advantage depends partly on credibility differentials: EU/U.S. buyers trust third-party SwRI verification more than Chinese state-backed certification. If China develops internationally recognized CAB infrastructure with equivalent audit rigor, Houston's trust premium erodes.

Monitoring indicator: Track acceptance rates of Chinese green certifications in EU procurement and investment decisions. If major EU manufacturers begin accepting Chinese carbon accounting without third-party verification, competitive dynamics shift fundamentally.

These are not risks to mitigate but conditions to monitor. If any proves false, the model requires fundamental recalibration rather than incremental adjustment. Acknowledging these dependencies is itself a form of intellectual honesty—good strategy names its assumptions explicitly, making them testable rather than hiding them in rhetoric.

VIII. Conclusion: Operating System vs. Specific Application

The architecture described here behaves differently than conventional infrastructure proposals in practice. Three design choices make this happen:

First: It treats coordination as an engineering problem, not a political aspiration. The three systems (MIP, Covenant, HIN) are technical specifications with measurable outputs: certification throughput, data interoperability, placement rates. This makes evaluation objective: either the system achieves its milestones or it doesn't.

Second: It acknowledges that failure modes are more likely than success scenarios. The stress tests in Section V deliberately probe weaknesses: fraud, policy reversal, infrastructure failure, competitive arbitrage. A robust system must demonstrate resilience to these shocks, not assume they won't occur. The identification of conditions that would make the model unviable—chronic infrastructure failures, weak CBAM enforcement, Chinese certification equivalence—is itself valuable strategic intelligence.

Third: It separates the architecture from specific instantiations. Houston is the first deployment site because conditions are favorable, but the pattern could adapt to Appalachian hydrogen economy, Permian Basin petrochemicals, or international manufacturing clusters in UAE, Vietnam, Indonesia. The transferable insight isn't "copy Houston" but a simpler and more uncomfortable one: if you want this kind of flywheel, you have to build trust infrastructure, coordination rules, and workforce systems at the same time, and wire them together.

MIP creates trust by making supply chains transparent and verifiable. Covenant creates coordination by aligning private incentives with shared workforce development. HIN creates efficiency by enabling data sharing without requiring data custody. Together, they form an operating system for industrial decarbonization—a framework that turns Houston's physical advantages into sustained competitive position.

The real test arrives in 2027-2028 when Phase 1 milestones come due: Will 500+ firms have enrolled? Will HITF demonstrate 75%+ placement rates? Will EU buyers pay premiums for MIP credentials? These are empirical questions, not rhetorical ones. The architecture's go/no-go gates ensure the market—not policy hopes—determines whether the experiment continues.

If it succeeds, Houston doesn't just become a low-carbon manufacturing center. It becomes the proof-of-concept for a new governance model where corporations, workers, and regions collaborate not through top-down mandates but through bottom-up coordination infrastructure. That's the paradigm shift hiding inside the technical specifications.

Copyright © 2025 Terawatt Times. All Rights Reserved. | ISSN 3070-0108

◀️ Previous Article | ▶️ Next Article | 📚 The Series Index

Authors

Alex is the founder of the Terawatt Times Institute, developing cognitive-structural frameworks for AI, energy transitions, and societal change. His work examines how emerging technologies reshape political behavior and civilizational stability.

Caroline is a Houston-born analyst focusing on Gulf Coast oil, LNG, and industrial electrification. She studies how legacy energy systems and new clean-power infrastructure reshape the economic future of the American South.

Sign up for Terawatt Times newsletters.

Stay up to date with curated collection of our top stories.