◀️ Previous Article | ▶️ Next Article | 📚 The Series Index

Executive Summary

Houston is emerging as the only U.S. region capable of executing a full industrial reshoring flywheel—where six structural advantages combine into a self-reinforcing system of growth. Its low-cost, high-volatility ERCOT grid enables electricity-intensive industries such as hydrogen, chemicals, and advanced manufacturing to operate at margins unattainable in Europe or East Asia. Port Houston adds a second foundation: the most predictable transit times of any major U.S. gateway, allowing manufacturers to reduce inventory, free capital, and cluster suppliers within a just-in-time logistics radius.

Agriculture, often overlooked, functions as a biological capital base whose cycles mirror industrial investment patterns and create opportunities for robotics spillover from Houston and Austin’s engineering talent pools. Pioneer capital from ExxonMobil, Shell, Tesla, and HyVelocity triggers Minimum Viable Density in suppliers, training programs, and specialized services, transforming the region into a self-sustaining manufacturing ecosystem. Emerging governance mechanisms—HETI, HyVelocity's Community Benefits Plan, and the proposed Houston Industrial Covenant—provide the coordination structure other regions lack.

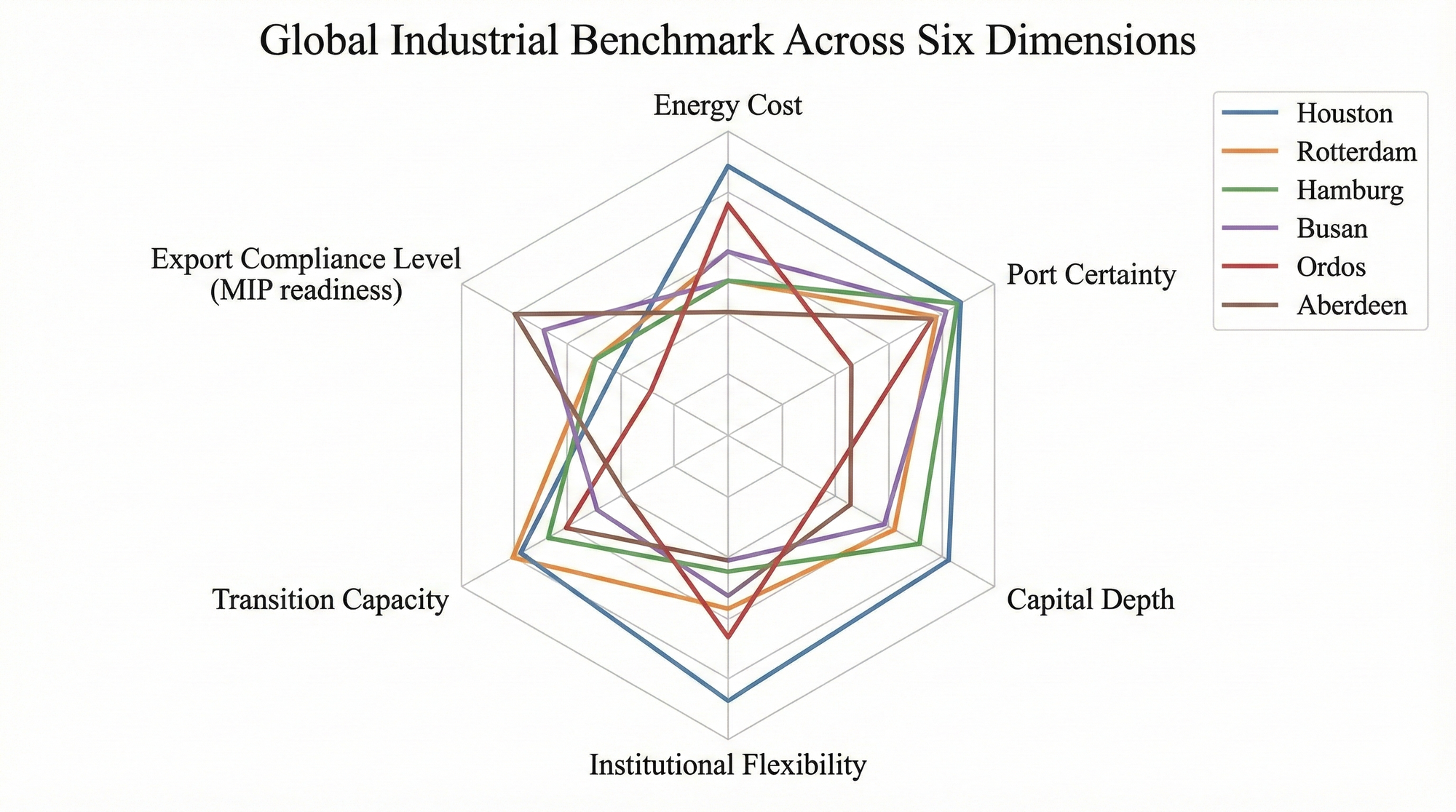

Global benchmarking shows competitors forced into specialization (Rotterdam, Hamburg), trapped by compliance gaps (Ordos), or pressured by rising energy costs (Busan, Aberdeen). Houston, by contrast, combines low cost, institutional flexibility, and capital depth. Its challenge is execution: deploying certification systems, enforcing the Covenant, and scaling a transition fund that unlocks the final loop of workforce mobility.

I. The Six-Dimensional Resource Matrix

Houston sits at a rare intersection of industrial advantages that no other American city can replicate. This isn't about having one or two strengths—it's about six dimensions aligning in ways that create exponential rather than additive value.

1. Energy Density: The ERCOT Advantage

Houston's energy advantage operates at three scales: the grid (ERCOT's market structure and pricing), the logistics system (how energy costs enable port economics), and industrial metabolism (which products become economically viable to manufacture). We start with the grid foundation, then trace cascading effects.

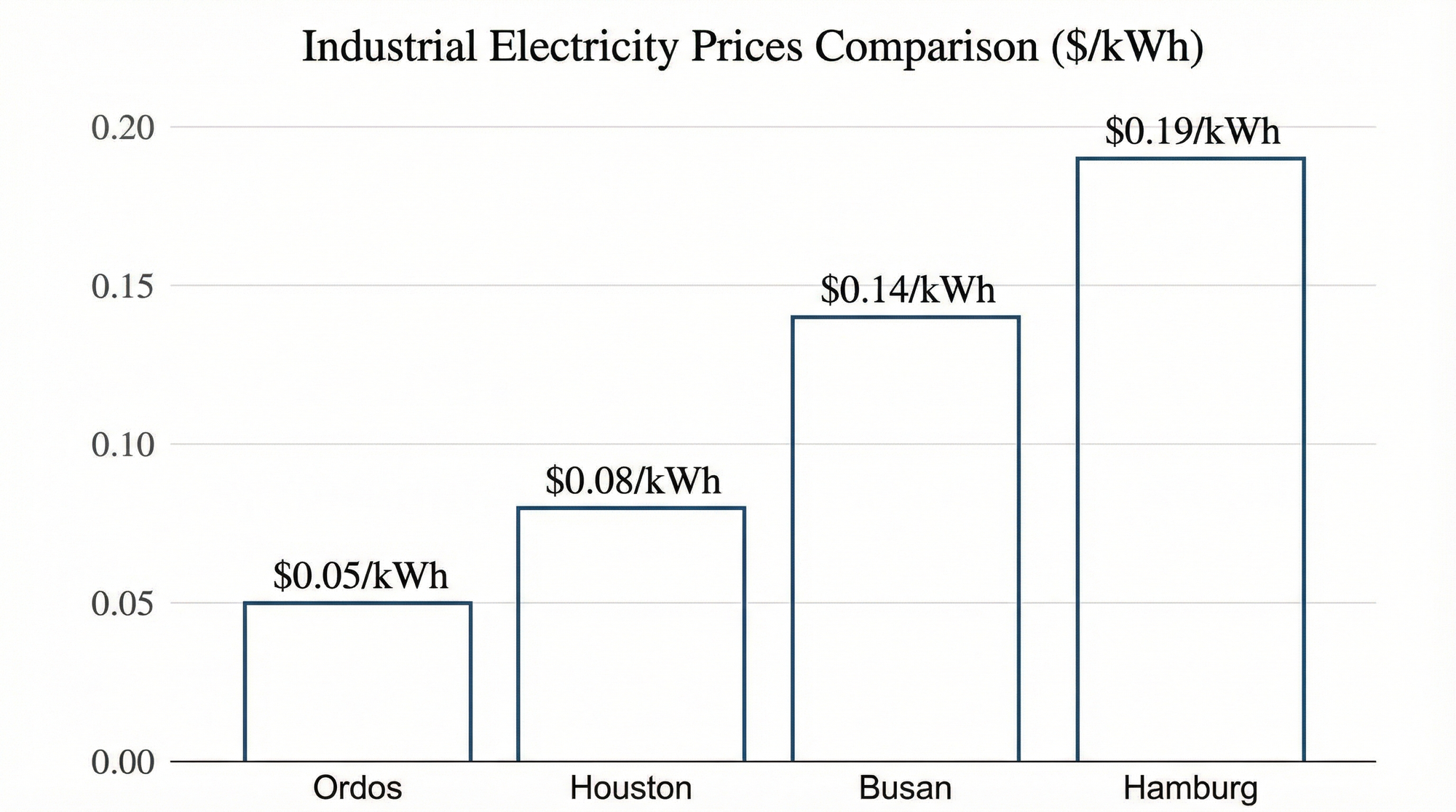

The Electric Reliability Council of Texas covers 90% of the state's load but operates isolated from the eastern and western interconnections. Industrial electricity in Houston trades around $0.08/kWh.[1] Compare this to competing regions: South Korea's Busan averages $0.14/kWh, Germany's Hamburg exceeds $0.19/kWh, while China's Ordos achieves $0.05/kWh in specialized renewable energy parks but with export logistics constraints.

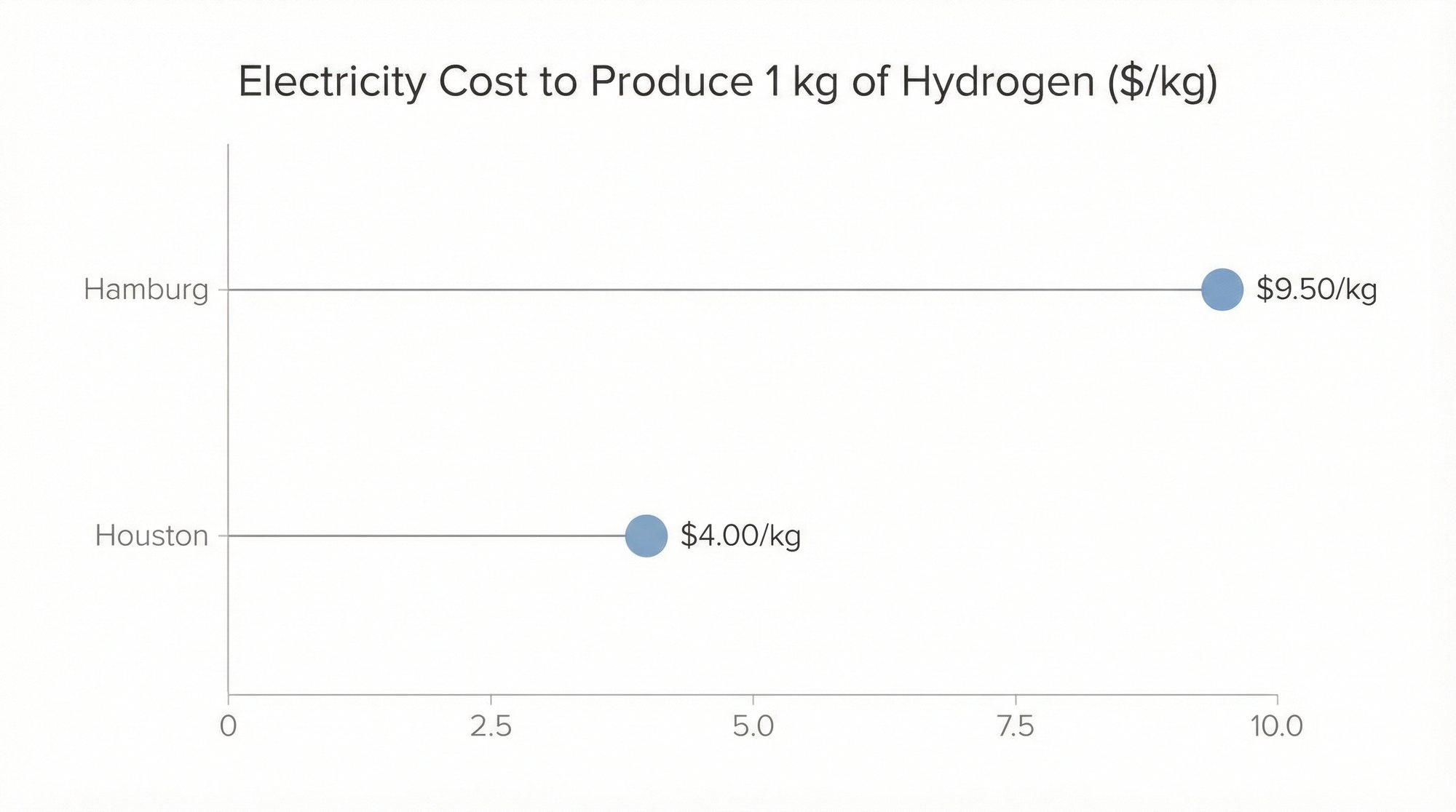

That $0.08/kWh matters because modern manufacturing is increasingly electricity-intensive. Green hydrogen production via electrolysis requires approximately 48-50 kWh per kilogram at commercial scale (NREL 2024 benchmarks), though industrial facilities often operate at 50+ kWh/kg due to system inefficiencies. At Hamburg's $0.19/kWh, producing one kilogram of hydrogen costs $9.50-10.45 in electricity alone. At Houston's $0.08/kWh: $4.00-4.40. That 55% cost differential determines which products can be manufactured where, not just profit margins.

The European Union's Carbon Border Adjustment Mechanism (CBAM) imposes $50-80 per ton of embodied carbon on imported chemical products, but Houston's response leverages ERCOT's rising renewable penetration—in 2024, over 40% of operational hours saw generation exceed 50% from wind and solar. This enables "low-carbon certified" products that avoid CBAM penalties while maintaining cost leadership. Low cost and low carbon becomes the foundation for export competitiveness.

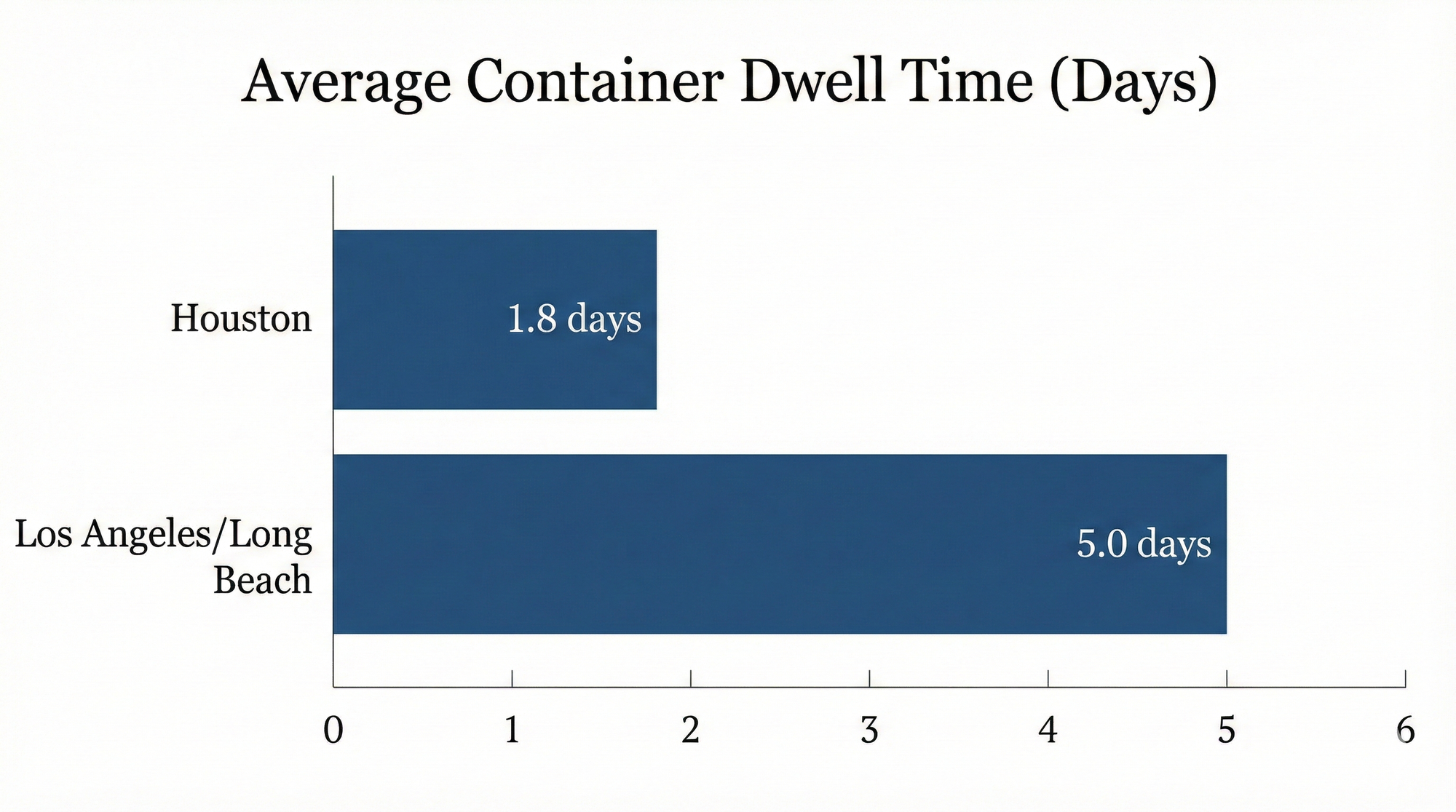

How energy reshapes logistics: In 2024, Port Houston moved 53.07 million tons of cargo, handling 4.14 million TEUs—an 8% increase making it the fastest-growing container gateway on the Gulf Coast. Houston has what LA/Long Beach lost: predictable transit times. During 2021-22 peak congestion, LA containers sat 9+ days. Even after improvements through 2024, dwell times typically run 2-4 days during normal operations, with occasional surges to 5-7 days during seasonal peaks. Houston maintains consistent sub-2-day dwell.

The difference isn't speed—it's certainty. A manufacturer facing 5-day variance must hold buffer stock worth hundreds of thousands of dollars. In Houston, that capital stays productive. This is the "certainty premium"—the economic value of knowing your container clears Tuesday morning, not "sometime this week."

Project 11—the Houston Ship Channel expansion—represents approximately $1.2 billion in federally-led construction widening the channel from 530 feet to 700 feet, enabling two-way Neo-Panamax traffic and eliminating daily navigation restrictions. December 2024 saw loaded exports surge 12%, hitting 135,446 TEUs. Houston's "resin corridor" fills empty import containers with petrochemical exports. LA/Long Beach pay $200-500 to reposition empties. Houston's repositioning cost approaches zero (minimal terminal handling ~$15/TEU).

Chinese imports through Houston reached approximately 30-34% of container market share in 2024 (TEU-based estimates from port throughput reports and trade data platforms; precise percentages vary by cargo classification and measurement methodology), reflecting diversification from West Coast dependency through a "Four Corners Strategy" hedging localized port disruptions.

2. Agricultural Capital: The Biological Asset Base

Texas held 12 million head of cattle on January 1, 2024—14% of the U.S. total and the nation's largest herd. The 4% decline from 2023 reflected biological capital cycle drawdown; by January 2025, the herd recovered to 12.2 million head. Cattle inventory follows a 3-5 year biological cycle where drought forces premature culling—analogous to industrial plant closures during recessions where short-term cash improves but long-term productive capacity erodes.

Texas operates 230,000 farms across 125 million acres. The "Food and Fiber System"—encompassing farm production through retail—contributed $240.3 billion to Texas GDP in 2023, representing 9.3% of state economic output, comparable to manufacturing's typical 12-15% share in industrialized states.

Agricultural automation represents untapped potential. Cattle ranching has seen minimal robotic penetration. Regional startup activity data from Austin Chamber of Commerce indicates increasing cross-pollination, with agricultural robotics founders citing recruitment from EV battery engineering talent pools. Texas Medical Center's life sciences capabilities combined with the state's agricultural dominance creates unique potential for precision livestock technology that doesn't appear in GDP statistics but represents real knowledge transfer.

3. Port Infrastructure: The Three-Speed Gateway

Port Houston operates at three speeds simultaneously. Speed one is container velocity—the Express Pass system targets 15-second gate transactions using OCR and RFID automation. By late 2024, adoption exceeded 85% of regular truck visits. Speed two is equipment modernization. Bayport approved $37 million for three new ship-to-shore cranes in 2024, with the 2040 master plan calling for 21 STS cranes and 84 RTGs at Bayport alone, pushing capacity beyond 4 million TEUs annually at that facility. Speed three is strategic rail connectivity to Dallas/Fort Worth and Chicago, offering shippers a hedge against LA/Long Beach congestion risk.

This three-speed approach creates network effects. Faster gates allow more truck turns. More cranes handle bigger vessels. Better rail connections expand catchment area. Each improvement makes the next more valuable, while making competing ports' investments less effective.

4. Pioneer Capital Deployment: The Anchor Tenant Effect

HyVelocity hydrogen hub received DOE designation with an initial award of $712 million, potentially reaching $1.2 billion contingent on staged milestones. Seven companies signed binding participation agreements: Chevron, ExxonMobil, Air Liquide, Sempra Infrastructure, Shell, Ørsted, and Mitsubishi Power. These contractually bind capital commitments and infrastructure sharing obligations. Sempra's Hackberry carbon storage ties to hydrogen production facilities, creating asset interdependence—neither project achieves adequate returns without the other.

ExxonMobil's Baytown blue hydrogen project plans to capture up to 5 million tons of CO2 annually in its initial phase, with infrastructure designed for potential expansion toward 10 million tons as the Gulf Coast CCS hub matures. The site operates 550 MW of cogeneration capacity producing 3.9 TWh yearly. Adding carbon capture and hydrogen production creates vertically integrated low-carbon industrial metabolism. Waste heat from refining powers chemical production. CO2 from hydrogen becomes feedstock or goes to permanent geological storage.

Tesla's Giga Texas demonstrates different pioneer capital deployment. Total planned investment exceeds $10 billion across 2,500 acres with over 10 million square feet. Annual production capacity reached 375,000 vehicles by early 2024. By end of 2024, cumulative production approached 350,000 units. Current ramp rates, based on supplier expansion announcements and regional job postings, suggest the facility could exceed 450,000 annual units by late 2025 if demand and supply chains support that throughput, a range consistent with independent industry analyst projections of 420,000-460,000 units for the facility.

But Giga Texas matters less for what it builds than for who it attracts. Plastikon Industries, Simwon North America, and Futronic established local facilities creating 350+ manufacturing jobs within a 30-minute logistics radius. The supplier network demonstrates cluster theory evolving beyond fixed thresholds like "5,000 suppliers." Cluster viability is about Minimum Viable Density (MVD)—the point where specialized support services self-organize.

MVD indicators:[2]

- Specialized HR firms: Kyle-Buda-Hutto area now has specialized staffing agencies offering "mechatronics technician placement" as a distinct service category—a niche barely existing locally in 2020

- Industrial real estate premium: Land parcels within 10 miles of Giga Texas command 15-22% higher per-acre prices than equivalent industrial land 30 miles away^3

- Community college response: San Jacinto and Austin Community Colleges launched mechatronics and industrial robotics programs without state grants—purely market-driven

When these third-tier services appear spontaneously, the cluster has crossed MVD and becomes self-sustaining.

5. Energy Transition Infrastructure: The Covenant Mechanism

The Houston Energy Transition Initiative (HETI) operates as governance infrastructure. The Greater Houston Partnership board combines oil majors (ExxonMobil, Chevron), renewable developers (Ørsted), and financial institutions (BBVA), tracking capital formation, job creation, and emissions reduction. BBVA's Houston sustainable finance center increasingly references HETI performance data in credit assessments. Companies demonstrating measurable transition progress gain reputational capital translating to improved access to green financing instruments.

HyVelocity's Community Benefits Plan (CBP) codifies this with contractual force. The $120 million CBP represents coordination mechanisms discussed across hydrogen hub proposals, with implementation details varying by region. Key proposed elements include Project Labor Agreements (union-scale wages and safety standards), Justice40 compliance (40% of benefits flowing to disadvantaged communities), and Community Advisory Boards with substantive input on benefit allocation.

DOE enforces commitments through staged "Go/No-Go" decision gates. Funding disburses in tranches tied to milestone achievement. If a hub fails commitments—insufficient local hiring, missed engagement targets, inadequate environmental monitoring—DOE can withhold subsequent funding. The scale of at-risk investment creates financial forcing functions: seven participating companies have billions in sunk capital facing potential stranded asset write-downs if federal funding terminates.

Beyond federal projects: The proposed Houston Industrial Covenant

HyVelocity demonstrates coordination for federally-funded projects. But what about Tesla's suppliers, petrochemical expansions, and logistics firms without federal contracts? The Houston Industrial Covenant would operate through conditional access to public goods and incentives:

Tier 1 Access (Standard): Available to all—standard port services, permitting, tax treatment.

Tier 2 Access (Priority Partners): Requires Covenant membership, providing priority port berthing (24-hour advance guarantee), express customs processing for MIP-certified cargo (significantly reduced clearance times, measured in hours rather than half-day cycles, compared to standard 8-12 hour processing), fast-track permitting (90-day maximum review), and workforce development program participation.

Tier 3 Access (Strategic Anchors): For companies with $500M+ annual regional revenue, adding reserved berth capacity, direct rail siding access, Port Houston capital allocation committee voting seats, and tax increment financing for multi-user infrastructure.

Covenant obligations include regional transition fund contributions (1-1.5% of Houston manufacturing wages), local hiring commitments (65% of new manufacturing hires from five-county metro), training program participation, and Houston Industrial Network data sharing.

A manufacturer shipping 1,000+ containers annually through Port Houston sees certainty premium worth $40-80K annually from reduced inventory carrying costs. Tier 2 access requires perhaps $150K annual contribution. For JIT manufacturing of high-value products—automotive components, electronics, pharmaceuticals—the certainty premium alone justifies membership. Add faster permitting and workforce pipeline access, and the value proposition becomes compelling.

6. Labor Market Depth: The Transition Cost Structure

Houston Community College offers Industrial Instrumentation Technology AAS (60 credit hours, two years) for approximately $8,000-9,000 in-state tuition (2024-25). San Jacinto College's Process Technology certificate requires 45 credits over 18 months, costing $3,500-5,000. These programs target oil and gas workers transitioning to automation and advanced manufacturing roles.

But the real cost isn't tuition—it's time. A two-year program means zero income for 24 months. For a worker earning $100,000+ in oil and gas (including overtime and hazard pay during boom periods), that's $200,000 in foregone earnings. Even after retraining, wage parity proves elusive. Houston instrumentation technicians earn $60,000-75,000 annually, with experienced technicians reaching $80,000+. Process analyzers command $75,000-90,000+, with top performers exceeding $100,000. These are solid middle-class wages, but don't immediately match peak oil sector compensation during boom cycles.

The skills transfer well. Oilfield pump operators understand hydraulics, pressure systems, and industrial safety. Drilling mud engineers know fluid dynamics and process control. The gap isn't technical competency—it's temporal cash flow and short-term economic pain.

Policy interventions target this friction. Texas Workforce Commission received $5.4 million in federal grants for advanced manufacturing, energy, and biotech training. But scholarships address the wrong problem. Tuition is already affordable. What's missing is transition period income support. European models offer 60-70% wage replacement during retraining. Without this, individual workers face a prisoner's dilemma: collectively, mass retraining benefits the regional economy, but individually, each worker is better off clinging to oil and gas employment.

The Covenant model solves this. Participating firms contribute 1-1.5% of payroll to Houston Industrial Transition Fund (HITF). Workers in approved programs draw 70% of prior wages (capped at $70,000 annually). Upon completion, graduates receive priority interviews at participating companies. These projections assume 80%+ anchor employer participation. Actual fund capacity would vary with economic cycles, with stress-testing suggesting minimum viable funding at 60% participation rates ($45 million annually). If Tesla and HyVelocity participants employ 60,000+ Houston workers at $85,000 average fully-loaded cost, 1.5% contribution at full participation generates $76.5 million annually. Supporting 1,000 workers through two-year programs at $49,000 annual stipend costs $49 million, leaving $27 million for program administration, partnerships, and reserves.

This transforms transition from individual gamble to collective insurance, breaking the prisoner's dilemma that keeps skilled workers trapped in declining sectors.

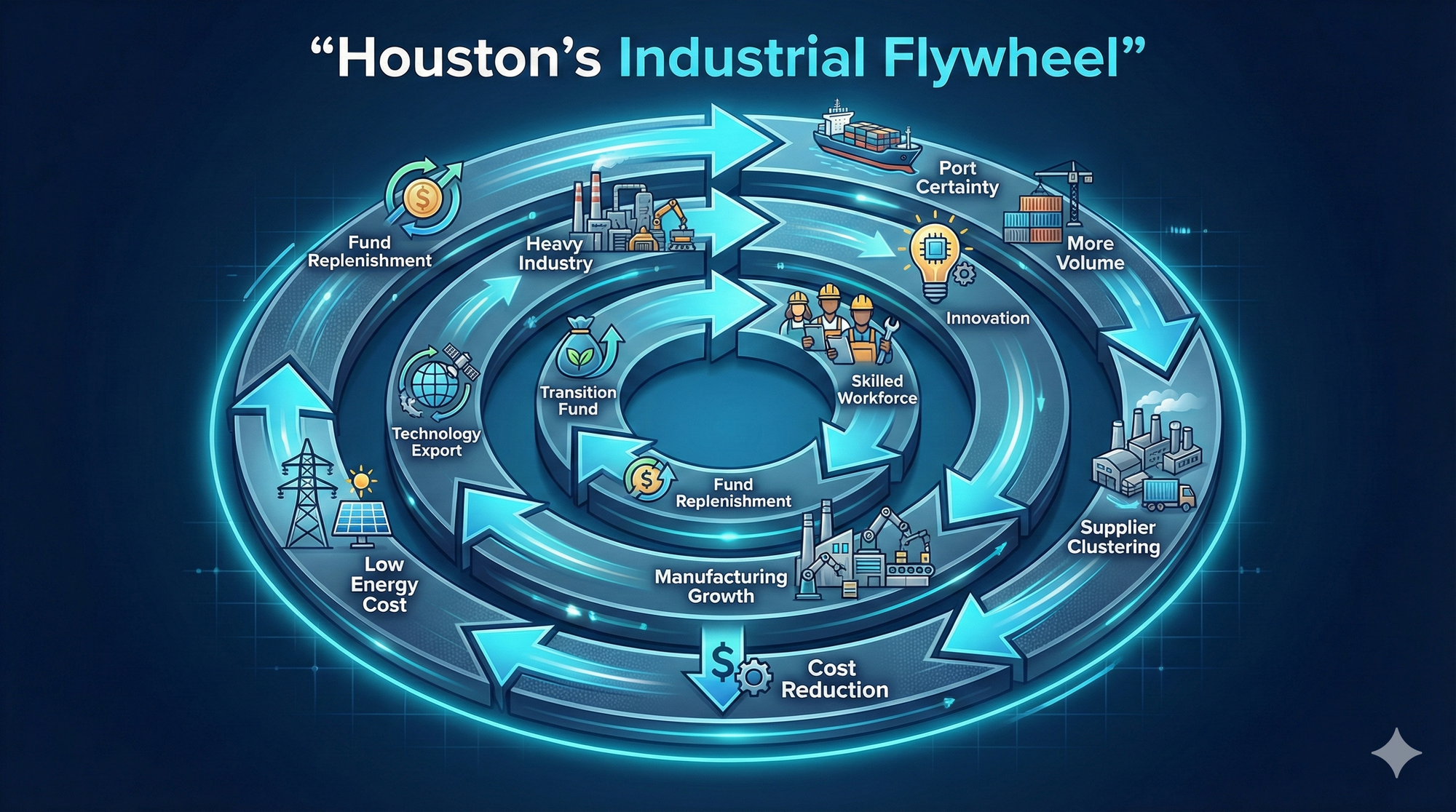

II. The Flywheel Mechanism: From Linear Advantages to Exponential Returns

Six advantages sitting separately deliver additive value. Combined with deliberate strategy, they create multiplicative returns through three reinforcing loops. The first two are spinning. The third represents the missing piece.

Loop 1: Port Certainty → Supplier Clustering → Cost Reduction → More Volume

Houston's predictable port operations lower working capital requirements. This represents theoretical calculation based on industry-standard inventory turnover formulas. Actual reductions vary by product type, order patterns, and supplier location. A Tesla supplier holding $2 million in monthly inventory under LA logistics could potentially reduce that to $1.2 million under Houston's 2-day dwell certainty—$800,000 in freed capital monthly, $9.6 million annually, available for capacity expansion or debt reduction.

Freed capital funds additional production lines. Capacity expansion attracts more suppliers—a mold shop serving three customers can't justify $500K precision CNC equipment, but serving eight customers makes it viable. Supplier density enables just-in-time manufacturing, further reducing inventory. When ten suppliers operate within 30 minutes, deliveries can occur four times daily instead of weekly, cutting on-site inventory 60-70%.

This loop accelerated post-2024. Chinese imports climbing to the 30-34% range means cargo owners actively reroute from West Coast ports. Each additional shipper improves Port Houston's bargaining power with carriers, securing better service commitments justifying continued infrastructure investments that cut dwell time further, attracting more volume.

The resin corridor amplifies this. Import containers leave filled with petrochemical exports at near-zero repositioning cost. This structural advantage compounds: lower costs → more carrier capacity allocation → more import volume → more empty containers → more export volume → lower per-TEU average costs.

Loop 2: Energy Cost → Heavy Industry → Innovation → Technology Export

At $0.08/kWh, Houston can profitably produce goods other U.S. regions cannot. Green hydrogen becomes economically viable. Aluminum smelting (13-15 MWh per ton) returns. Data centers offer computational services below competitors' marginal costs.

When energy cost falls by half, optimal production scale changes. Larger plants achieve efficiencies smaller competitors can't match, naturally concentrating industry in low-cost regions. Concentration enables specialization. Specialized suppliers (high-pressure hydrogen valves, explosion-proof industrial robotics, parts-per-billion chemical sensors) establish local presence, enabling new anchor tenants to start faster and cheaper.

Innovation spillover is measurable through labor market signals. When engineers move between ExxonMobil, Tesla, and suppliers, tacit knowledge about automated production, quality control, and supply chain coordination spreads through informal networks. Community colleges observe demand patterns and launch new programs. The regional economy moves up the value curve as an emergent property of density.

Loop 3: Transition Fund → Workforce Availability → Manufacturing Growth → Fund Replenishment

This loop doesn't exist yet—it's the missing piece. Its design logic emerges through HyVelocity's CBP, HETI's workforce initiatives, and Gulf Coast precedents. If implemented through the Covenant mechanism, it would operate as follows:

Anchor firms contribute 1-1.5% of payroll to HITF. The fund pays 70% wage replacement to workers in approved retraining programs. Graduates gain priority access to jobs at contributing firms through Houston Industrial Network platform matching. As more manufacturing jobs are created, more workers enroll in training, increasing the skilled labor pool. Larger skilled workforce attracts more firms. More firms mean more payroll contributions, increasing fund capacity.

The mechanism is self-balancing. If too many workers train relative to openings, manufacturing wages rise, naturally increasing training enrollment. If too few workers train, labor shortages drive wages up, attracting more applicants. The 70% wage replacement acts as a thermostat maintaining equilibrium.

Why doesn't this exist yet? Collective action problems. Any single firm funding transition benefits all firms (free rider problem). The Covenant solves this by making participation a condition for accessing public goods: priority port services, expedited permitting, preferential tax treatment. This converts voluntary coordination into a precondition for market access.

When all three loops operate simultaneously, they create exponential rather than additive returns. Loop 1 lowers operating costs, freeing capital. Loop 2 determines which industries can locate in Houston. Loop 3 ensures those industries can actually hire. Remove any single loop: the flywheel stalls or spins at fractional speed.

III. Global Benchmarking: Houston vs. Five Industrial Rivals

To appreciate Houston's positioning, compare it against five hubs attempting similar transformations. These represent three archetypes:

| Archetype | Cities | Core Characteristics | Houston's Strategy |

|---|---|---|---|

| High-Cost Efficiency Hubs | Rotterdam, Hamburg | Electricity >$0.19/kWh; forced specialization | Maintains low-cost base enabling multi-product portfolio |

| Low-Cost Compliance-Gap Zones | Ordos | Ultra-low electricity ($0.05/kWh) but export certification barriers | Combines low cost with full export market access |

| Transition-Squeeze Regions | Busan, Aberdeen | Rising energy costs erode traditional competitiveness | Proactive transition from position of strength |

Rotterdam: High-Cost Efficiency Hub

Rotterdam's port industrial cluster generates €30.6 billion GVA—3.2% of Dutch GDP. Industrial electricity costs around $0.19/kWh, more than double Houston's rates. Rotterdam compensates through radical efficiency and carbon infrastructure. The Porthos CCS project and Delta Rhine Corridor hydrogen pipeline target 4.6 million tons annual hydrogen supply by 2030. Port's 2023 industrial carbon emissions fell 10% (2.2 million tons reduction).

But cost structure forces specialization. Rotterdam can't compete in energy-intensive base materials. Instead, it becomes a carbon management services hub—offering CCS infrastructure, hydrogen distribution, green certification. This is value-added trading and services, not primary production. Houston can do both: produce at low cost and offer carbon management services.

Ordos: Zero-Cost Energy Oasis

Ordos demonstrates what happens at $0.05/kWh electricity in specialized renewable parks. The Envision Zero Carbon Industrial Park is scaling toward multi-hundred-billion RMB annual output in renewable energy equipment manufacturing. But Ordos faces a critical constraint Houston doesn't: the "MIP deficit" (Machine-readable Industrial Passport). Chinese manufacturers produce at lowest cost but struggle to certify supply chain compliance for European markets. Without forensic verification proving ethical sourcing, labor standards, and accurate carbon footprints, Ordos products face market access barriers.

Houston's advantage lies in straddling both worlds. Energy costs approach Chinese levels (only 60% higher), but regulatory infrastructure and certification capabilities match European standards. The $0.03/kWh gap between Ordos and Houston narrows substantially when accounting for export logistics (landlocked Inner Mongolia vs. direct Gulf Coast shipping), IP protection (enforced in U.S., often weak in China), and market access premiums (CBAM, USMCA rules of origin).

Busan: Transitional Pressure Point

Busan-Jinhae Economic Free Zone generated 12.13 trillion won in industrial output (2021), representing over 40% of Busan's total. Korean industrial electricity hit $0.14/kWh in Q1 2025—up sharply as KEPCO absorbs renewable transition costs. Rising energy costs squeeze traditional heavy industries. The government's policy pivot toward semiconductors and batteries represents a bet on high-value products that can absorb higher energy costs per unit output. But this creates stranded assets—refineries, steel mills, and chemical plants optimized for cheap baseload energy now operate at structural disadvantage.

Houston faces the opposite trajectory. ERCOT's competitive wholesale market keeps costs low even as renewable penetration increases. The grid accepts price volatility—spot electricity occasionally goes negative during high wind/solar production. Manufacturers with flexible loads arbitrage these swings, lowering effective average costs further.

Hamburg: Forced Premium Position

Hamburg's port cluster supports approximately 110,000 jobs generating roughly €12-13 billion GVA. German industrial electricity frequently exceeds $0.19-0.21/kWh. Hamburg's high energy costs intensify Germany's long-standing specialization in precision engineering and high-complexity manufacturing, rather than creating that specialization from scratch. If labor productivity increases 30% through automation, and automation capex is 40% lower due to German engineering expertise, Hamburg maintains competitiveness despite energy costs. But only in sectors where automation yields dramatic productivity gains—aircraft components, precision machinery, specialized chemicals. This reinforces high-complexity, lower-volume production while shedding bulk manufacturing capacity.

Houston's trajectory diverges. Instead of forced specialization, Houston maintains both mass production (petrochemicals, hydrogen, industrial gases) and high-tech manufacturing (EVs, batteries, advanced electronics). When Chinese competition intensifies in commodity chemicals, Houston can shift capacity to specialty chemicals. When European demand for certified low-carbon products grows, Houston supplies that premium tier.

Aberdeen: Survival Transition Laboratory

Aberdeen's Energy Transition Zone received £17.3 million in UK government funding in 2025, targeting 2,500 direct green jobs and 10,000 regional transition-related positions by 2030. This is survival strategy, not growth strategy. North Sea oil faces terminal decline. The £10,000-per-company training subsidies reveal scale difference—£17.3 million total versus Houston's proposed $75+ million annual transition fund. Aberdeen represents reactive policy. Houston represents proactive coordination—industry investing ahead of crisis because alignment makes cooperation rational.

Houston starts from strength, not desperation, with time to execute transition deliberately, using oil and gas cash flows to fund renewable infrastructure while maintaining profitability. The Covenant mechanism formalizes what Aberdeen lacks: binding commitments from anchor employers to absorb transitioning workers, backed by economic incentives making compliance rational rather than charitable.

IV. The Strategic Synthesis: Why Only Houston Can Execute the Full Flywheel

Three factors distinguish Houston from rivals—structural endowments creating compound effects.

Energy Cost Asymmetry as Categorical Variable: At $0.08/kWh versus $0.14-0.19/kWh elsewhere in developed economies, Houston captures margin on every kilowatt-hour. This isn't slight advantage—it's categorical difference determining which products are economically viable to manufacture. Green hydrogen at 50 kWh/kg: Hamburg's production cost is $9.50/kg electricity, Houston's is $4.00/kg. That $5.50/kg gap exceeds the entire gross margin for most chemical products. You can't "innovate around" a cost difference that exceeds profit margin. The CBAM complication doesn't eliminate this advantage—it reshapes it. A Houston producer spending $1/kg on MIP certification still delivers hydrogen at $5/kg total cost versus Hamburg's $9.50/kg before any certification costs.

Institutional Flexibility: ERCOT's market structure allows industrial users to capture spot market benefits impossible in regulated utilities. When wind generation floods the grid and prices go negative, a hydrogen electrolyzer can ramp to maximum output and get paid to consume electricity. Port of Houston's governance as independent entity enables rapid infrastructure investment without legislative gridlock. Texas's regulatory pragmatism permits faster permitting than California, New York, or European equivalents. A chemical plant expansion in Houston completes permitting in 18-24 months versus 36-48+ months in California's Bay Area.

Capital Depth and Running Transition: Existing oil and gas infrastructure represents trillions in sunk investment. Rather than stranded assets, these become platforms for transition. ExxonMobil's Baytown complex adds CCS, hydrogen production, and low-carbon product lines while maintaining profitable traditional operations. This "running transition" beats Rotterdam's "cold conversion" or Aberdeen's "emergency pivot." Capital depth also provides patient funding for long-cycle projects. Houston billionaire families and sovereign wealth funds with Texas exposure provide patient capital for industrial projects with 10-15 year payback periods.

The flywheel emerges from integrating these factors with pioneer investments. HyVelocity supplies low-carbon feedstock to existing chemical plants while enabling new clean industrial processes. Port Houston's container growth supports both traditional oil and gas equipment exports and emerging renewable energy manufacturing equipment. Tesla's supplier ecosystem creates automation expertise transferable across industries.

Most critically, the Covenant mechanism—once implemented—solves the coordination problem that dooms other transition attempts. Without it, individual firms face prisoner's dilemmas: invest in local training that competitors benefit from, or free-ride on others' investments? The Covenant makes contribution mandatory for accessing public goods, aligning incentives.

Houston's six-dimensional advantage creates possibility, not certainty. Realization depends on operational execution: MIP certification infrastructure, Covenant enforcement mechanisms, and coordinated data architecture. Whether potential converts to kinetic motion—that is the question the region must answer in the coming decade.

[1] Based on ERCOT wholesale market averages for industrial customers, 2024. Actual delivered costs vary by location and consumption patterns. Houston's petrochemical corridor can see $0.085-0.092/kWh including congestion charges during peak periods.

[2] Based on regional job posting analysis and staffing agency service offerings, 2023-2025 comparison. ^3 Industrial real estate premium estimates based on CoStar commercial property data and regional broker reports, 2024-2025.

Copyright © 2025 Terawatt Times. All Rights Reserved. | ISSN 3070-0108

◀️ Previous Article | ▶️ Next Article | 📚 The Series Index

Authors

Alex is the founder of the Terawatt Times Institute, developing cognitive-structural frameworks for AI, energy transitions, and societal change. His work examines how emerging technologies reshape political behavior and civilizational stability.

Caroline is a Houston-born analyst focusing on Gulf Coast oil, LNG, and industrial electrification. She studies how legacy energy systems and new clean-power infrastructure reshape the economic future of the American South.

Sign up for Terawatt Times newsletters.

Stay up to date with curated collection of our top stories.